Pretty Plastic transforms waste into enduring facade claddings

Pretty Plastic is a Dutch company founded by designers Reinder Bakker and Hester van Dijk from Overtreders W and architect Peter van Assche from Bureau SLA. The company was established with the mission to transform waste into valuable building materials, specifically focusing on creating sustainable facade cladding from recycled PVC. Pretty Plastic's current mission is to champion the circular economy by converting construction waste into beautiful, durable, and safe building products. Core values include sustainability, innovation, and responsibility, with a purpose to reduce waste and promote circularity in the construction industry.

Location

Headquarters: Amsterdam, Netherlands.

Primary manufacturing/operations locations: Various locations across the Netherlands.

Note: Strategic location in the Netherlands to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

Key innovations: Development of facade tiles made from 100% recycled PVC, innovative manufacturing processes, and the use of recycled aluminum for rear wall constructions.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using local materials and production to minimize environmental impact and support local economies.

Pioneering Solutions

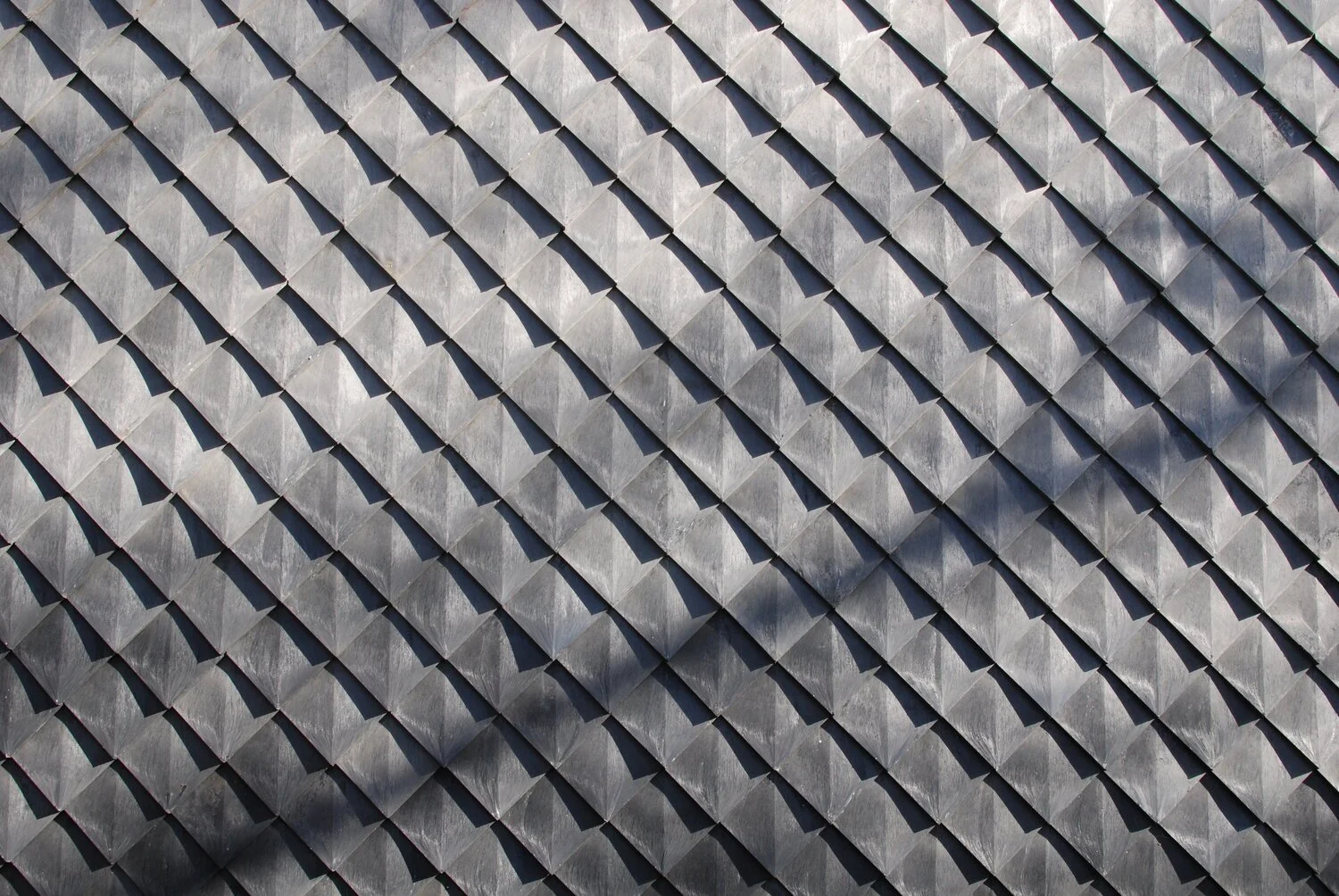

Flagship products: Pretty Plastic facade tiles, including the First One, Second High, and Basic Third tiles.

Unique value propositions: High-quality, sustainable cladding solutions that prioritize circularity, material reuse, and environmental responsibility. Pretty Plastic's products are known for their unique aesthetics, durability, and ease of installation.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, developing new sustainable materials, and optimizing circular design processes.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available globally through direct sales and partnerships with distributors.

Environmental Product Declaration (EPD): Available for Pretty Plastic tiles, providing transparency on environmental impacts.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: Information not available.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled PVC.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production.

Key Takeaway

Pretty Plastic transforms construction waste into high-quality, sustainable facade cladding, setting a benchmark for circularity and environmental responsibility in the building industry.

Explore Further

Pretty Plastic website: https://www.prettyplastic.nl

Sustainability overview: https://www.prettyplastic.nl/about-us

Example product: Pretty Plastic facade tiles - https://www.prettyplastic.nl/products

Pretty Plastic is a Dutch company founded by designers Reinder Bakker and Hester van Dijk from Overtreders W and architect Peter van Assche from Bureau SLA. The company was established with the mission to transform waste into valuable building materials, specifically focusing on creating sustainable facade cladding from recycled PVC. Pretty Plastic's current mission is to champion the circular economy by converting construction waste into beautiful, durable, and safe building products. Core values include sustainability, innovation, and responsibility, with a purpose to reduce waste and promote circularity in the construction industry.

Location

Headquarters: Amsterdam, Netherlands.

Primary manufacturing/operations locations: Various locations across the Netherlands.

Note: Strategic location in the Netherlands to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

Key innovations: Development of facade tiles made from 100% recycled PVC, innovative manufacturing processes, and the use of recycled aluminum for rear wall constructions.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using local materials and production to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: Pretty Plastic facade tiles, including the First One, Second High, and Basic Third tiles.

Unique value propositions: High-quality, sustainable cladding solutions that prioritize circularity, material reuse, and environmental responsibility. Pretty Plastic's products are known for their unique aesthetics, durability, and ease of installation.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, developing new sustainable materials, and optimizing circular design processes.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available globally through direct sales and partnerships with distributors.

Environmental Product Declaration (EPD): Available for Pretty Plastic tiles, providing transparency on environmental impacts.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: Information not available.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled PVC.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production.

Key Takeaway

Pretty Plastic transforms construction waste into high-quality, sustainable facade cladding, setting a benchmark for circularity and environmental responsibility in the building industry.

Explore Further

Pretty Plastic website: https://www.prettyplastic.nl

Sustainability overview: https://www.prettyplastic.nl/about-us

Example product: Pretty Plastic facade tiles - https://www.prettyplastic.nl/products

Pretty Plastic is a Dutch company founded by designers Reinder Bakker and Hester van Dijk from Overtreders W and architect Peter van Assche from Bureau SLA. The company was established with the mission to transform waste into valuable building materials, specifically focusing on creating sustainable facade cladding from recycled PVC. Pretty Plastic's current mission is to champion the circular economy by converting construction waste into beautiful, durable, and safe building products. Core values include sustainability, innovation, and responsibility, with a purpose to reduce waste and promote circularity in the construction industry.

Location

Headquarters: Amsterdam, Netherlands.

Primary manufacturing/operations locations: Various locations across the Netherlands.

Note: Strategic location in the Netherlands to optimize local sourcing, distribution, and collaboration with industry partners.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating products that are fully recyclable.

Key innovations: Development of facade tiles made from 100% recycled PVC, innovative manufacturing processes, and the use of recycled aluminum for rear wall constructions.

Prioritization of local sourcing and closed-loop supply chains: Emphasis on using local materials and production to minimize environmental impact and support local economies.

Pioneering Solutions

Flagship products: Pretty Plastic facade tiles, including the First One, Second High, and Basic Third tiles.

Unique value propositions: High-quality, sustainable cladding solutions that prioritize circularity, material reuse, and environmental responsibility. Pretty Plastic's products are known for their unique aesthetics, durability, and ease of installation.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, developing new sustainable materials, and optimizing circular design processes.

Ambitious goals: To lead the construction industry in sustainable practices, create zero-waste products, and inspire a shift towards a regenerative built environment.

Fact Sheet

Commercial Availability: Products available globally through direct sales and partnerships with distributors.

Environmental Product Declaration (EPD): Available for Pretty Plastic tiles, providing transparency on environmental impacts.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: Information not available.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled PVC.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through sustainable materials and local production.

Key Takeaway

Pretty Plastic transforms construction waste into high-quality, sustainable facade cladding, setting a benchmark for circularity and environmental responsibility in the building industry.

Explore Further

Pretty Plastic website: https://www.prettyplastic.nl

Sustainability overview: https://www.prettyplastic.nl/about-us

Example product: Pretty Plastic facade tiles - https://www.prettyplastic.nl/products