Smile Plastics is a materials design and manufacturing house

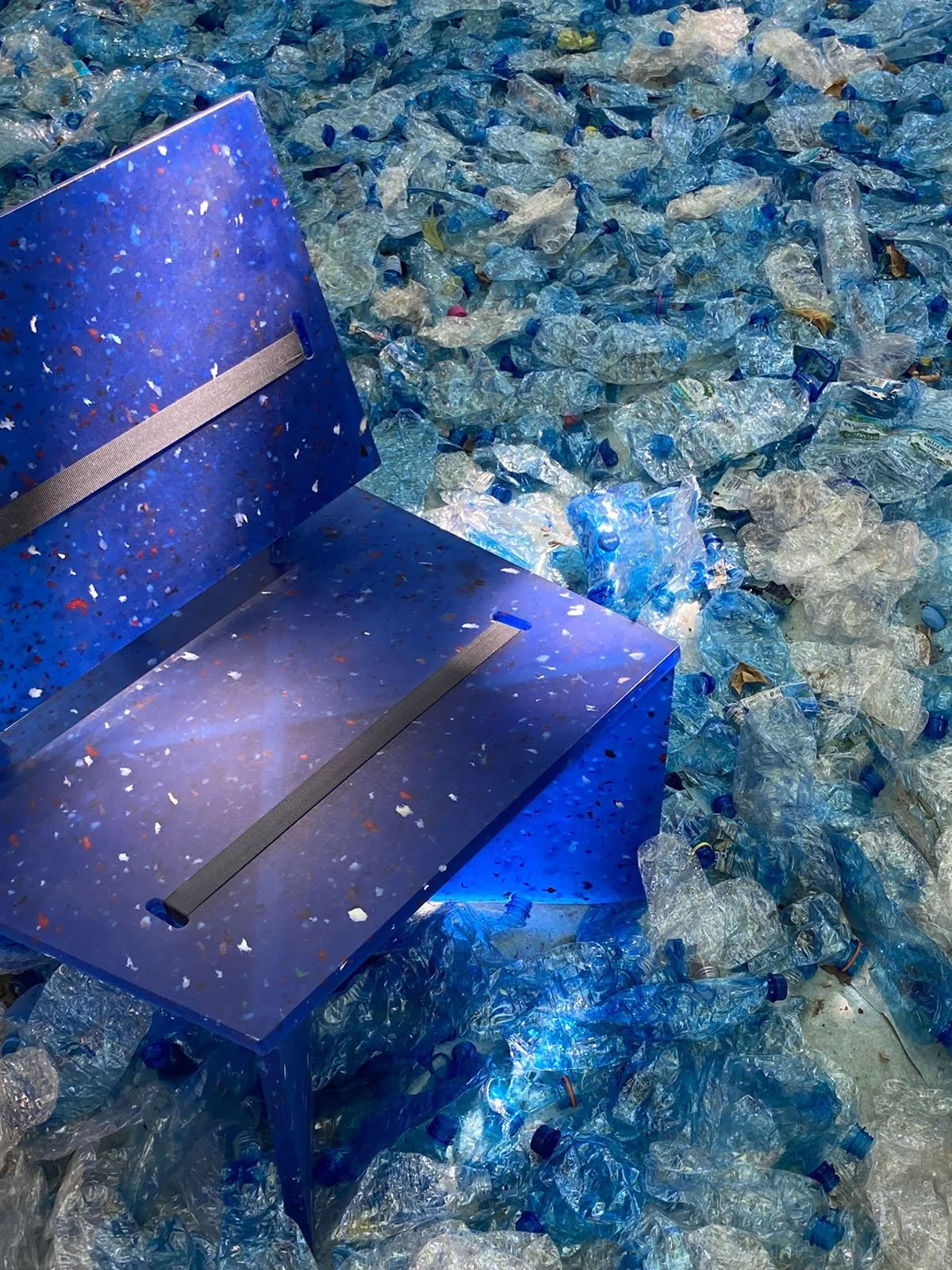

Smile Plastics was first established in the early 1990s by engineer Colin Williamson and designer Jane Atfield, creator of the recycled-plastic RCP2 Chair (now in the V&A's permanent collection). For almost two decades, the company led the way in showcasing the design potential of recycled plastic, until Colin's retirement in 2010. In 2015, the then-dormant brand was revived by Adam Fairweather and Rosalie McMillan, employing new processing techniques and low-energy manufacturing technology that enable rapid, high-volume production via a continuous, 24/7 batch process. Smile Plastics' mission is to rediscover the beauty and functionality hidden in materials traditionally classed as 'waste', working towards the circular economy by designing and making distinctive architectural panels and aesthetic surface products from pre- and post-consumer waste.

Location

Headquarters: Swansea, Wales, United Kingdom.

Primary manufacturing/operations locations: Factory on the southwest coast of Wales.

Note: Strategic location in Wales to maintain local talent, community, and supply chains while optimizing production capacity.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating fully recyclable products.

Key innovations: Proprietary process to transform waste plastics into aesthetic, functional, and recyclable surfaces, selective blending of waste plastics to create distinctive patterns.

Prioritization of local sourcing and closed-loop supply chains: Sourcing waste materials from over 60 local businesses, community groups, and organizations around Swansea and beyond.

Pioneering Solutions

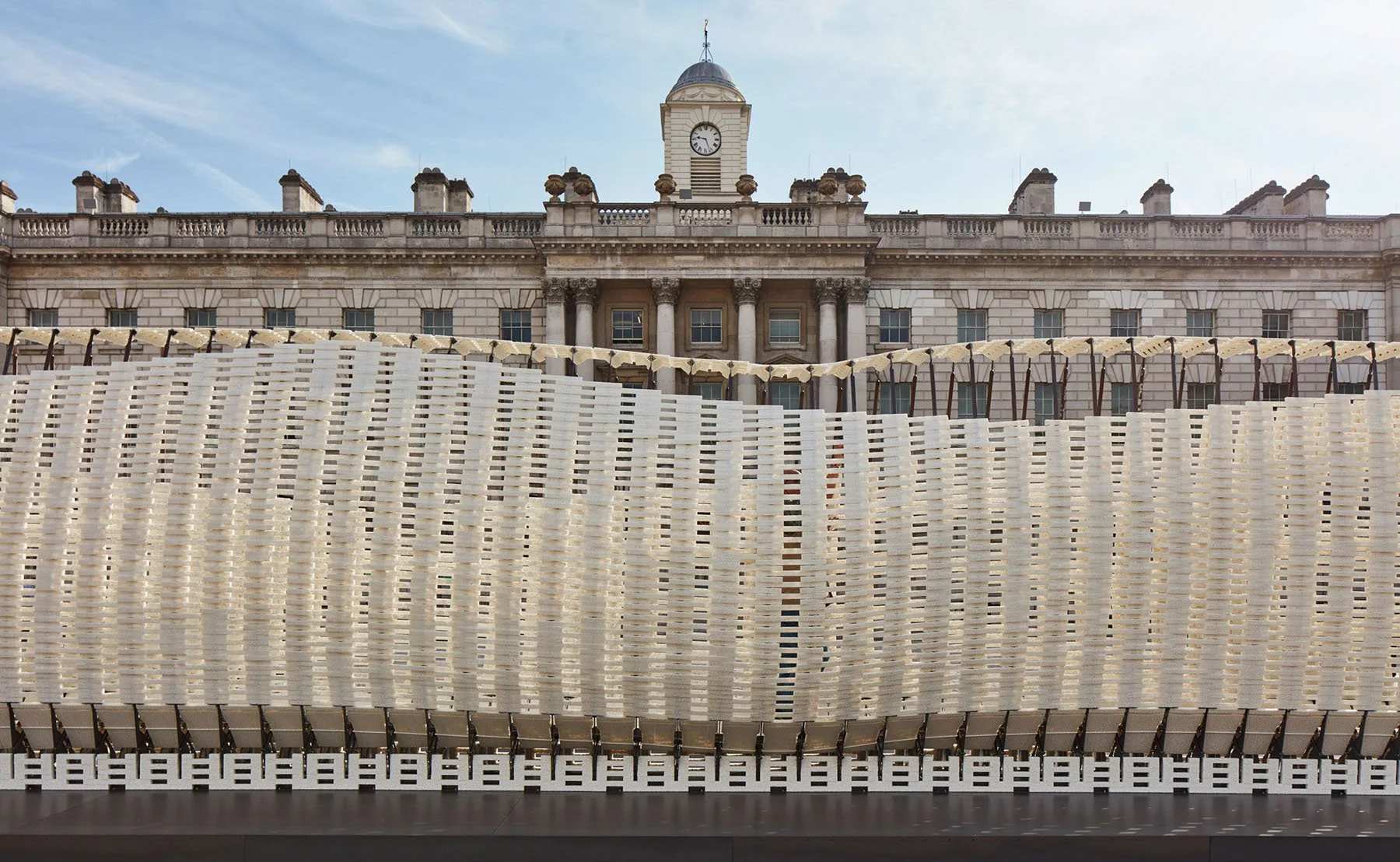

Flagship products: Recycled plastic panels and sheets for various applications like countertops, furniture, signage, and construction.

Unique value propositions: High-quality, sustainable materials made from waste plastics, unique surface patterns reflecting the materials' former lives, easy to work with and maintain.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, developing new sustainable materials, and optimizing circular design processes.

Ambitious goals: To see an end to single-use plastic and the global adoption of a circular ecosystem where all existing plastic can be infinitely recycled.

Fact Sheet

Commercial Availability: Products available globally for architects, designers, and luxury brands.

Environmental Product Declaration (EPD): Available for high impact polystyrene and polyethylene terephthalate materials.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: ISO 14001, REACH compliance.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled plastics.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through low-energy manufacturing and local production.

Key Takeaway

Smile Plastics is a pioneering company that transforms waste plastics into high-quality, sustainable surfaces, setting a benchmark for circularity and environmental responsibility in the design and construction industries.

Explore Further

Smile Plastics website: https://www.smile-plastics.com

Sustainability overview: https://smile-plastics.com/sustainability/

Example products: https://smile-plastics.com/materials

Smile Plastics was first established in the early 1990s by engineer Colin Williamson and designer Jane Atfield, creator of the recycled-plastic RCP2 Chair (now in the V&A's permanent collection). For almost two decades, the company led the way in showcasing the design potential of recycled plastic, until Colin's retirement in 2010. In 2015, the then-dormant brand was revived by Adam Fairweather and Rosalie McMillan, employing new processing techniques and low-energy manufacturing technology that enable rapid, high-volume production via a continuous, 24/7 batch process. Smile Plastics' mission is to rediscover the beauty and functionality hidden in materials traditionally classed as 'waste', working towards the circular economy by designing and making distinctive architectural panels and aesthetic surface products from pre- and post-consumer waste.

Location

Headquarters: Swansea, Wales, United Kingdom.

Primary manufacturing/operations locations: Factory on the southwest coast of Wales.

Note: Strategic location in Wales to maintain local talent, community, and supply chains while optimizing production capacity.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating fully recyclable products.

Key innovations: Proprietary process to transform waste plastics into aesthetic, functional, and recyclable surfaces, selective blending of waste plastics to create distinctive patterns.

Prioritization of local sourcing and closed-loop supply chains: Sourcing waste materials from over 60 local businesses, community groups, and organizations around Swansea and beyond.

Pioneering Solutions

Flagship products: Recycled plastic panels and sheets for various applications like countertops, furniture, signage, and construction.

Unique value propositions: High-quality, sustainable materials made from waste plastics, unique surface patterns reflecting the materials' former lives, easy to work with and maintain.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, developing new sustainable materials, and optimizing circular design processes.

Ambitious goals: To see an end to single-use plastic and the global adoption of a circular ecosystem where all existing plastic can be infinitely recycled.

Fact Sheet

Commercial Availability: Products available globally for architects, designers, and luxury brands.

Environmental Product Declaration (EPD): Available for high impact polystyrene and polyethylene terephthalate materials.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: ISO 14001, REACH compliance.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled plastics.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through low-energy manufacturing and local production.

Key Takeaway

Smile Plastics is a pioneering company that transforms waste plastics into high-quality, sustainable surfaces, setting a benchmark for circularity and environmental responsibility in the design and construction industries.

Explore Further

Smile Plastics website: https://www.smile-plastics.com

Sustainability overview: https://smile-plastics.com/sustainability/

Example products: https://smile-plastics.com/materials

Smile Plastics was first established in the early 1990s by engineer Colin Williamson and designer Jane Atfield, creator of the recycled-plastic RCP2 Chair (now in the V&A's permanent collection). For almost two decades, the company led the way in showcasing the design potential of recycled plastic, until Colin's retirement in 2010. In 2015, the then-dormant brand was revived by Adam Fairweather and Rosalie McMillan, employing new processing techniques and low-energy manufacturing technology that enable rapid, high-volume production via a continuous, 24/7 batch process. Smile Plastics' mission is to rediscover the beauty and functionality hidden in materials traditionally classed as 'waste', working towards the circular economy by designing and making distinctive architectural panels and aesthetic surface products from pre- and post-consumer waste.

Location

Headquarters: Swansea, Wales, United Kingdom.

Primary manufacturing/operations locations: Factory on the southwest coast of Wales.

Note: Strategic location in Wales to maintain local talent, community, and supply chains while optimizing production capacity.

The Circular Vision

Core circular economy principles: Designing out waste, using recycled materials, and creating fully recyclable products.

Key innovations: Proprietary process to transform waste plastics into aesthetic, functional, and recyclable surfaces, selective blending of waste plastics to create distinctive patterns.

Prioritization of local sourcing and closed-loop supply chains: Sourcing waste materials from over 60 local businesses, community groups, and organizations around Swansea and beyond.

Pioneering Solutions

Flagship products: Recycled plastic panels and sheets for various applications like countertops, furniture, signage, and construction.

Unique value propositions: High-quality, sustainable materials made from waste plastics, unique surface patterns reflecting the materials' former lives, easy to work with and maintain.

The Regenerative Future

R&D focus areas: Advancing recycling technologies, developing new sustainable materials, and optimizing circular design processes.

Ambitious goals: To see an end to single-use plastic and the global adoption of a circular ecosystem where all existing plastic can be infinitely recycled.

Fact Sheet

Commercial Availability: Products available globally for architects, designers, and luxury brands.

Environmental Product Declaration (EPD): Available for high impact polystyrene and polyethylene terephthalate materials.

Circularity Rating: 5/5 (Designed for full circularity).

Key Certifications: ISO 14001, REACH compliance.

Cost Rating: 4/5 (Competitive with conventional alternatives, with significant cost savings in sustainable materials).

Material Passport: Detailed material traceability and use of recycled plastics.

Designed for Disassembly: Yes, products are designed for easy disassembly and recycling.

Carbon Performance: Focus on reducing carbon footprint through low-energy manufacturing and local production.

Key Takeaway

Smile Plastics is a pioneering company that transforms waste plastics into high-quality, sustainable surfaces, setting a benchmark for circularity and environmental responsibility in the design and construction industries.

Explore Further

Smile Plastics website: https://www.smile-plastics.com

Sustainability overview: https://smile-plastics.com/sustainability/

Example products: https://smile-plastics.com/materials